Due to some technical errors, the previous posting has been deleted. This is a repost

Synthetic Materials

What is your take?

|

| Walrus Ivory Nut |

|

| Walrus Ivory Nut |

Part 2 is expected to be slightly technical… While I am aware that not everyone will enjoy reading technical stuffs, such information does provide both wider and deeper comprehension of saddle materials in relation to tonal characteristics. This can further narrows the subjectivity tendencies in selecting the suitable saddle materials to match one's preference. During my study on saddle materials, I have reviewed several literatures written by anthropologists and other researchers that have conducted extensive study onto these materials. The sources are attributed at the end of this posting. For those who wish to know more, you're encouraged to read those resources. Herein I will attempt to elaborate the ever elusive saddle materials and tone from these perspectives.

- Brief introduction of Acoustics

- Acoustic properties of materials

- Properties of the various saddle materials.

- Sound clips - Bone and Ivory

|

| Particles transmitting vibration energy |

Firstly, we all know that sound is produced when an object vibrates. The vibration pushes surrounding air particles, and these particles oscillate which spreads like ripple effects, the oscillation gets passed on between adjacent particles until the initial vibration energy is completely dissipated. Our ears detect such particle movements as sound. Guitar saddles function to transmit strings vibration energy to the guitar top plate (wood) resulting the vibration of top plate. We hear guitars through this energy transfer process. However energy loss is inevitable during the process of vibration transfers. Saddle materials are no exception to that. Perhaps it could very well be due to the inherent energy loss for each material that is different from others that sets each apart. While sound energy can be transferred via various mediums, this article concerns saddle materials, which are solids.

About Acoustic Properties of Materials

Many properties affect the eventual acoustic properties of any given materials. Herein I am featuring three prime properties in determining if a given material transfers sound energy or absorbs it. Understanding it is essential to predicting the tonal characteristics of saddle materials. However, there is no attempt to rank these featured saddle materials.

The three properties are density, rigidity and porosity.

1. Density - a measure of mass per unit volume of material. Dense materials allow efficient transfer of sound energy. Low density materials tend to absorbed part of the sound energy in making the particles within the material to vibrate.

2. Rigidity - a measure of resistance to deformation by external force of a given material. Malleable (Non-Rigid) materials can absorb sound energy in making the particles within itself to vibrate, which is similar to low density materials. Conversely, rigid materials can transfer sound energy through their material structure with little loss.

3. Porosity - a measure of the quantity of empty spaces (air gaps) in the total volume of a material. This is the most tricky property of the three. For a highly porous material, it is made up of very dense and rigid molecular structures. Adjacent to these dense and rigid molecular structures are air voids, too small to be observed by naked eyes. Rigid molecular structures promote efficient sound energy transfer with minimum absorption (loss). However the air voids within have created changes of energy propagating medium from solids to air voids (a.k.a. changes in surface impedances). This isn't good for energy transfers if the path way is subject to many impedance changes. Invariably materials of low porosity doesn't guarantee superb sound energy transfer because density and rigidity must promote it as well. Suffice to say that the relationships between porosity and efficient transmission of energy is far more complex.

Those who wish to read on, the following sections will cover the various saddle materials widely used in the present market. I have made no attempt to do any review but report the researched and known facts related to each featured material herein. There are unlimited literatures on this topic and my version may not align with many others. Also please don't take my writings wholesale, be curious to verify and even recommend corrections. In this way, everyone will learn and hopefully inclining to greater accuracy in creating such literatures. The following saddle materials will be featured in the next few sections.

Plastic (Synthetic)

Synthetic Ivory (Synthetic)

Pyrolytic Carbon (Synthetic)

Pyrolytic Carbon (Synthetic)

Brass (Alloy)

Bones (Natural)

Horns (Natural)

Ivories (Natural)

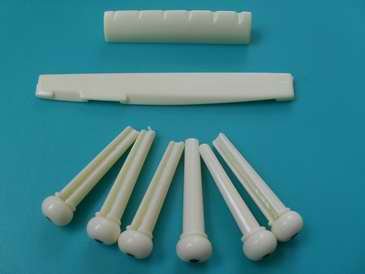

Synthetic Materials

1. Plastic - Actually it is a by-product of crude oil refinement process. Polyethylene a.k.a. plastics have surely changed our lives. Its versatility has made it relevant. One such application is the injection molding process. Just about any plastic you hold in your hands is made through the molding process. By going in large volume, plastics products can achieve speed in production, volume in production, consistencies and most importantly reduction in cost per plastic product produced. While there are various grades of plastics, they are pretty much viewed by laymen as similar.

In making guitar saddles, the moldable nature of plastic has overwhelmed all other materials regardless of their merits. Just about any shape can be made out from plastics. As such, plastic saddles of any kind are seen flooding the guitar markets relentlessly. A huge attraction to guitars manufacturers indeed. In terms of properties relating to acoustic qualities, due to plastics' general low rigidity, it will be hard to claim that plastic saddles can enable a guitar to fully express herself. The density and rigidity of plastics are usually not close to regular natural materials like bones, ivories and horns. While these two attributes are main influences to acoustic properties of any given materials but they are still not the determinant ones.

It is also difficult to describe the tonal characteristics from plastic saddles except to predict more sound energy loss is expected. Suffice to say that changing to harder and denser materials with known acoustic properties, improvements are noticeable immediately. However plastic is here to stay regardless..

|

| Plastic parts |

2. Pyrolytic Carbon - it is a diamond like carbon base synthetic material that has undergone a treatment process call pyrolysis. The treated materials are enhanced in certain mechanical properties. The patent of this process is held by James M. Guthrie and Jonathan C. Stupka, both are based in Austin Texas, USA. The company behind the development of this material is Obbligato Inc. also based in Austin Texas, USA (http://www.obbligatoinc.com/).

Elaborated in the patent, pyrolysis is inducing decomposition of hydrocarbon at temperature in excess of 1000˚ C. In this state, carbon molecules can be coated on a suitable substrates of dense isotropic graphite, also of suitable size and shape which include various guitar parts. The coating can be of structural or surface nature. The process in which they are made will likely result in increase in rigidity and density but porosity is not conclusive. This carbon base material bears a trademarked name "Black Diamond" because of the way the material is synthesized. These are the claims regarding tonal and functional enhancements for applications to musical instruments.

≈ significant increase in volume

≈ gives richer harmonics

≈ clearer sound, reduce muddiness

≈ strings sound lively for a loner period before going "dead"

≈ gives strings coming to contact with such materials longer life-span

Taken from: http://www.obbligatoinc.com/images/Saddle_FV.jpg

Taken from: http://www.obbligatoinc.com/images/DiamondSaddlecrop.jpg

| Pyrolytic Carbon a.k.a. Black Diamond |

|

| A Black Diamond Saddle |

Source: Pyrolytic Carbon Components for Stringed Instruments Patent, USPTO # is 8,110,729.

I wasn't able to obtain any empirical data to verify the above claims but given the method which it is synthesized, the Black Diamond is likely to give any organic material a run for its money.

Clarification; the above section has been amended from synthetic ivory to pyrolytic carbon. Factually, it is incorrect to classify pyrolytic carbon as synthetic ivory.

Clarification; the above section has been amended from synthetic ivory to pyrolytic carbon. Factually, it is incorrect to classify pyrolytic carbon as synthetic ivory.

3. TUSQ, a material well known to many guitar players, also widely called man-made ivory, is produced by Graphtech, a Canadian company. Graphtech has employed this patented TUSQ technology for more than 30 years in producing many guitar parts. TUSQ has similar enhancements as claimed by the pyrolysis process. Likewise I wasn't able to find any empirical date to support those claims. However the popularity of TUSQ has certainly been established strongly among musicians. Anecdotally, one may find it hard to deny its qualities by the sheer popularity.

3. Brass - it is an alloy of copper and zinc known for its superior acoustic properties. This wonderful materials carries many favorable properties that have magically fitted into man's evolution. As man became more knowledgeable, the application of brass also widens and deepens. Its great versatility in industrial and commercial applications has made it indispensable.

|

| Brass nut |

While many musical instruments are made out of brass, it is not known if it was the malleability or acoustic properties of this materials that made brass the top choice for making metal musical instruments, perhaps both characteristics have contributed. As for acoustic properties, brass does carry certain properties like strength, elasticity, density that are favorable to sound energy transfer too. There are other metals that possess similar basic properties but they don't make the grade of musical instruments. The history of brass in relation to metal musical instrument is indisputable. Brass saddles are rare but nuts are commonly seen.

Natural Materials

The next sections, I will provide a simplified summary of each natural saddle materials. Instead of focusing on merely acoustic properties and tonal qualities when applied as guitar saddles, understanding the fundamental make up will help in making sense of the tonal characteristics of these natural saddle materials when in use. After all, acoustic properties of any given materials are all but an extension of their fundamental make up.

|

| Bone parts |

4. Bones - It is a dense type of connective tissue made up of 1/3 organic tissues and 2/3 inorganic salt components. This wonderful substance provides functions like support, protection, movement assistance, mineral storage, blood cells production and chemical energy storage. Porosity and density of bone are not uniform for all bones. It is because of the unique functional applications of various bones located at different body parts that render its variable porosities and densities. Besides the structural function undertaken by our bones, blood irrigation is one of the many essential functions as well. This explains the porosity nature of bones.The bones for making guitar saddles are compact bones that has the mechanical and acoustic properties to meet the expectations.

|

| Horn saddle |

5. Horns - It is composed of a sheath of keratin overlying a bony core. Keratin is a class of resistant and insoluble fibrous protein. These keratin tissues are usually associated with various essential biological functions e.g. offense, defense, display, communication, temperature and water regulation. In fact, there are other body parts which constitute keratin tissues as their make up, e.g. feather, hair, claws, nails but in this article, the feature item is bovid horn. It is not regenerative unlike nails or hair. The growth of horn is also made possible because of the presence of organic tissues which deliver nutrients and minerals to it. Unique to bovid horns, moisture content within can have significant influences on its overall strength.

|

| FMI Nut |

|

| FWI Saddle |

6. Ivories (Elephant, Mammoth, Mastodon, Walrus) - It is a calcified substance which possesses a complex chemical and structural composition. In material science terms, ivory is a rigid biological composite, has a rigid matrix reinforced by elastic fibers. Its strength comes from calcium phosphate found in the rigid matrix and its elasticity is due to discontinuous collagen fibers. The application of tusk (before they become ivory) during their active days include functions like pushing, piercing, bending and bearing its own weight. The make up of ivories is also like bones or bovid horns consist of both inorganic and organic tissues. It is almost made entirely of dentine, coated with a layer of cementum. Within the dentine core, pulp cavity takes up about 1/3 of the entire tusk length, beginning at the pulp rostral. The growth of tusks are enabled by the delivery of nutrients and mineral via the dentine pulp.

Tonal Characteristics

The above three natural saddle materials are found to be dense in general. Each one possesses high strength and elasticity due to the functional requirements during the active days of each. It may not be squarely considered as a rigid material nor soft as well. Within each one, it is made up of both organic and inorganic constituents for its initial growth years. The porous nature of each enables nutrients irrigation thus growth is possible.

In relation to the tonal characteristics of each material, it is all about recognition and differentiation. This is also the main issue. The process of recognition and differentiation is all but a subjective preferential cognitive process. Far from perfect but this is what we have. Not withstanding our subjective preferences, each material does carry it unique characteristics that are influenced by the fundamental make up, density, rigidity, strength and porosity. As objective and factual as I can, below are my two cents of each material, largely base on my experiences in working with them and the data table below.

|

| Data Table |

Bones are denser than ivory (see above table), thus also heavier for a given unit of volume. In terms of rigidity, bone has higher Elastic Modulus than ivories which accounts for its stiffness and hardness. Taken from Maury Music's website on saddle materials' review, "Bone saddles offer very pure tone, nice volume and an increase in sustain…" I interpret pure tone as loud, clarity and unaltered. What is yours? In relation to bone's acoustic properties, its high density and rigidity are likely contributive to the tonal characteristics. As for porosity, it is inconclusive.

Ivories, the common ones use in acoustic guitars are Fossilized Mammoth, Fossilized Walrus and Elephant. Compared to bones, usually their densities and rigidities are less but not far from it. However ivories are known to be tougher than bones in terms of fractures, i.e. high in elasticity strength. While bone is observed to give pure tone, ivories tend to influence the tonal signature of guitars. Taken from Maury Music website on saddle materials' review, "They add warmth and fullness, fatting up the notes and compensating for any brittle qualities one might hear…" and also " If there is a downside to fossilized ivory it is found in highest highs. Some of the brightness and sparkle, what I call the angels in the harmonics over top of the voice, is sacrificed in exchange for that added warmth and meat in the undertone and fatness in the fundamentals."

The link to Maury Music's saddle review article: http://www.maurysmusic.com/fossilized_mammoth_ivory_saddle___todd_s_review

We can loosely conclude that ivories are softer than bones because bone fractures more readily than ivories. In a paper written on the physical characteristics of mammoth ivory (Heckel C., 2009), bone specimens when subjected to percussions by hammerstone fractured. Whereas ivories were able to take more blows and cracks were seen propagating before fractures finally set it. This amazing property is indicative of ivories ability to absorb mechanical energy. Personally, I think this unique ability has resulted in the tonal distinction mentioned in saddle materials review article.

Here are two audio clips for your listening pleasure. The only difference between both clips is the saddle material. Here is the recording chain regarding the clips. Remember to raise your device volume if you can't hear the clips optimally.

Guitar: Gibson Western Classic

Mic: Zoom Q3

Amplificaton: Unplugged

Instrumental Tune: 31-91 by Hardline

Clip one: With FMI saddle

Clip two With Bone saddle

What is your take?

|

| Buffalo Horn Saddle |

Bovid horns are least rigid compared bones and ivories. In handling the blanks, they can be readily bent, unlike the stiffness of bones and ivories. However, bovid horns' are still considerable stiff, tough and strong because of the functional demands of horns. Hydration significantly affects the stiffness. Water penetrates the intertubular matrix, acting as plasticizer thereby reducing density and stiffness of bovid horn. Well in laymen terms, horn feels softer. Sound energy transfers 101, more sound energy loss is expected from bovid horn materials. When translated to tonal characteristics of guitar, one would expect less volume but the other characteristics are anyone's guess.

Brass possesses higher levels in strength, rigidity and density than all natural saddle materials. Moreover brass's acoustic properties are indisputable. When used as guitar saddles, the heavy weight is expected to increase sustain, boost clarity and volume. However, it is harder to make a brass saddle by hand than those natural materials. It might be this practical reason that brass is not commonly used as guitar saddles.

Closing

My conclusion is similar to part 1 in essence. While we can put in tremendous effort in quantifying the properties and normalizing the way we describe the materials, there is no escaping from our preferential judgment on such intrinsic attributes. There isn't much difference in loving someone where it is all in the eyes of the beholder. In my effort to condense the abundance of literatures that are related to the topic of saddle materials, I hope this article is able to provide fresh angles and insights to all guitar lovers. To some individuals, judging should be solely base on irrefutable facts and data whereas on the other end of spectrum, some individuals are totally comfortable in using subjective perspectives, jargons and intuition. Part 1 has given attention to subjectivities and part 2 has attempted to link mechanical properties and acoustic properties of various saddle materials to the eventual tonal characteristics of guitars. If you are able to find your preferred tone and saddle materials after reading this article, it would be the greatest reward for me. It was indeed an interesting ride for me. Thank you for reading!

Sources

Acoustic Properties of Materials: http://www.crecim.cat/portal/images/MaterialsScience/public/Acoustics_module_3rd_version_en.pdf

Measurement of the Acoustic Properties of Acoustic Absorbers: http://www.inceusa.org/nc07/links/Muehleisen_plenary_acoustic_properties_materials.pdf

Bone Structure and Composition: http://www.eng.tau.ac.il/~gefen/BB-Lec1.PDF

Tensile Properties and Facture of Ivory: http://www.springerlink.com/content/l3112460j86446nx/

Physical Characteristics of Mammoth Ivory and their Implications for Ivory Work in the Upper Paleolithic: http://www.urgeschichte.uni-tuebingen.de/fileadmin/downloads/GfU/2009/071-092.pdf

Experimental study on the mechanical properties of the horn sheaths from cattle: http://jeb.biologists.org/content/213/3/479.full.pdf

Classical Guitar Forum thread about nut and saddle material: http://classicalguitar.delcamp.net/viewtopic.php?f=11&t=61655&start=15

The effects of material in brass instrument: http://la.trompette.free.fr/Smith/IOA/material.htm

Acoustic properties of common metals: http://www.efunda.com/materials/common_matl/Common_Matl.cfm?MatlPhase=solid&MatlProp=Acoustic#Acoustic

Physics of musical instruments: http://hyperphysics.phy-astr.gsu.edu/hbase/music/musinscon.html#c1

About brass: http://www.copperinfo.co.uk/alloys/brass/brasses-properties-and-applications.shtml#s3

Measurement of the toughness of bone: A tutorial with special reference to small animal studies: http://www.lbl.gov/ritchie/Library/PDF/bone_tough_bone_08.pdf

Structure and functions of bones: http://www.ivy-rose.co.uk/HumanBody/Skeletal/Skeletal_System.php

What is bone? : http://www.mananatomy.com/basic-anatomy/bone

What are cow horns? : http://www.cowboyway.com/What/CowHorns.htm

Structure and innervation of the tusk pulp: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1571488/

Microstructure, elastic properties and deformation mechanisms of horn keratin: http://www.rhinoresourcecenter.com/pdf_files/126/1263373670.pdf

Maury Music, FMI Guitar Saddle Review: http://www.maurysmusic.com/fossilized_mammoth_ivory_saddle___todd_s_review

One aspect you do not consider is the mass of the saddle material. If the saddle is 'massive', wouldn't that directly affect the resonant frequency of the top of the guitar? I would that would be a consideration, especially for brass.

ReplyDeleteThanks for your query. There are actually many factors to consider. Mass was indeed in my train of thoughts. While I don't claim that I have proven anything absolutely, my experiences with heavy materials (implied to be dense) are have shown inconclusive results in enhancing tonal properties. After all, louder sound doesn't meaning better. Strangely but consistent, when I use brass bridge pins instead of brass saddle, the noticeable improvement was consistently the tonal sustain. As for the organic materials for saddle, they carry a common property, i.e. they are hard and tough, unlike glass which is hard and brittle. The collagen fibers found in these organic material does provide this unique combination of hardness and toughness. This has led me to assume that such property may be essential for guitar saddle. I have yet to establish the actual cause from material engineering standpoint. May be I would never get there. But the hundreds of guitars I have fitted with saddles of organic materials have yield mostly positive results from my clients. I think this is just as relevant. My two cents. I welcome your thoughts.

ReplyDeleteHi,What do you think of Nubone? It's also mfg by Graphtech.

ReplyDeleteHi wifiabc,

ReplyDeleteHere is an excerpt from Graphtech's website on NuBone, "Nubone is a derivative of Graph Tech's proprietary TUSQ material and offers very similar tonal characteristics to our highly esteemed TUSQ." Hope that answers your query.

The baseline fact is the base material used for creating TUSQ is the same as NuBone. It highlighted many merits that overlapped with TUSQ. So in making an educated guess; I shouldn't expect drastic differences.

Cadam7777777, you did not read well the "Black Diamond" patent nor did you read much about pyrolytic carbon and DLC.

ReplyDelete"Black Diamond", the trademark name chosen by the company Obbligato, is only a commercial name for a certain grade of pyrolitic carbon and in no possible way would it be diamond-like-carbon (DLC) not any form of synthetic diamond in existence.

DLC aka diamond-like-carbon is NOT produced via pyrolisis of organic precursors (whereas pyrolitic carbon is exclusively produced via pyrolisis -hence the name- of pitch or manmade polymers) , it is comprised of an array of very small diamond aggregates or clusters (hence diamond bonds are present) while pyrolitic carbon has only grahitic type of bonding (graphene layers bonded in a different manner than natural graphite)

-Mechanical properties of DLC and pyrolitic carbon have almost nothing in common besides relative density and being comprised of carbon.

Obbligato claims pyrolitic carbon is not carbon fiber, which is a tricky phrase, since carbon fiber is a particular form of carbon produced via pyrolysis with mostly graphite type of bonds , but the general structure is different than that of "pyrolytic carbon", although bonding is generally of graphitic type (it can be understood as an array of graphene plates ordered in a different manner than in natural graphite).

this has absolutely nothing in common with any form of diamond whether natural nor synthetic, apart being made of pure carbon.

You're the only one claiming that Obbligato's "black diamond" is diamond like carbon, as they never once did in their patent: they describe only specific grades of pyrolitic carbon / pyrocarbon which is deposited on specific graphite substrates . It is clear thi type of product (the substrate nor the coating) has nothing to do with DLC (diamond like carbon).

Please check your sources next time!

Obbligato should be able to respond to your claims.

DeleteI'm not claiming anything, but you are certainly making incorrect guesses on a subject you do not understand very well to say the least.

DeleteThe real problem is you managed to get fooled by obbligato's trademarked name "black diamond" thinking it's some form of diamond thus you making this bold guess that it would be DLC (DLC is famous for it's black color, but honestly this shows how far the public is unaware of other forms of "black" graphitic and or diamond related products: graphene is black, glassy carbon -amorphous in nature- is as well, "carbonado" -a form of natural diamond- is black too, etc etc)

Read a bit, man, all the existing literature available on carbon states that DLC is mostly sp3 bonds (common dlc coatings are somewhere near 75-80% diamond bonds) and the rest being sp2 (graphitic bonds). This means it is an amorphous product being comprised of a majority of tiny diamond clusters in a matrix of graphitic bonds holding everything together, whereas pyrolytic graphite is 100% graphitic bonds and absolutely no diamond bond whatsoever, the only difference with natural graphite being the way the graphene layers are connected and stacked. To enlighten you even further, know that graphene sheets can be "extracted" by exfoliating plates of pyrolytic graphite.

Nowhere , neither in the patents nor on the website, does Obbligato claim in any way that their product coined "black diamond" would be really diamond, on the contrary they explain that it is an undisclosed grade of PYROLYTIC GRAPHITE , --not-- DLC as you tried to guess , sharing your incorrect conclusion with fellow guitarists. Don't say that a company is claiming things that you are the only one to believe.

Dear Xaar,

DeleteI am opened to learn from you as well. Just to make it clear about applying common sense as well. At this point, it would be unwise to take all your claims and arguments without a clue of your identity and and much less any knowledge of your impetus in this exchange. My email is listed, if you are comfortable to have a proper intellectual exchange, like other parties who have written to me about righting facts, I look forward to hear from you.

Dear Cadam77777 , I am extremely surprised you are taking this discussion into the dreaded "who's who" game.

ReplyDeleteI am even more surprised that you didn't take 10 poor minutes of you time looking up in materials handbooks what DLC and pyrolitic carbon are and how they are produced undustrially. Only 2 minutes of reading a few "vulgarized" articles about these aformentioned materials on Azom.com would have at least put you iun the right direction.

The best thing for you would be to start off with a few articles listing the definitions of various carbon related materials, then to buy download or rent at the library a dedicated book written by research teams, such as the great classic "Handbook of Carbon, Graphite, Diamonds and Fullerenes: Processing, Properties and Applications " ISBN: 0815513399 , any edition will do.

Look up all the turbostratic carbon forms and -alakazaam- pyrolytic carbon will appear under its many synonyms such as "pyrolytic graphite" or even "pyrocarbon", right next to graphitized rayon and other carbon/graphite fibers, which are all 100 % graphitic in nature without the slightest HINT of diamond anywhere to be seen in them (which is normal if you read the procedures and conditions involved: temperature, method of deposition and or firing, pressures needed etc) .

Then look up DLC coatings and you'll se they're not turbostratic and are considered amorphous although not glassy (DLC is one type of diamond microcrystals dispersed in a graphite matrix holding the diamond clusters or microcrystals together, the balance between the diamond and graphite in quantitative terms is tipping seriously towards diamond naturally).

If you had looked up the subject you'd know there's a big debate in the industry between pyrolytic carbon and DLC ( and a few other materials) in the world of artificial heart valves. Each company tries to sell their specialized coating claiming it's more biocompatible, withstands wear (from use, body fluids, etc) better, than the other coatings available on the market. DLC is clearly NOT graphitic carbon and you'd be the laughing stock of the industry if you said out loud that they are the same thing, but wait you've just claimed it on your blog along with a few other funny assertions pertaining to materials.

If you need more book titles about synthetic carbon materials,JUST ASK ME, no need to know "who I am" or whatever out of topic info you're trying to get out of me.

Happy reading and see you soon.

Cadam77777, if you feel the former post (the one where I give you the book title with ISBN) and the present one shouldn't be published on the blog , well don't.

ReplyDeleteI simply didn't find your email, the same way you didn't look up the info before writing up your article ;)

But at least read the damn book or just the chapters tha concern the subject in question!

Dear Xaar,

ReplyDeleteYou're indeed explicitly zealous in pointing out the gaps in the article. For that I think your effort should be appreciated. Thus far you have given extensive amount of information on this topic. Probably some information is beyond my comprehension due to the lack of direct exposure and experiences. However it would not be appropriate to discount the validity of the other source. I shall welcome your continuous thoughts, assertion and criticism freely within this platform. It remains that you're anonymous to me and I wish that I understand the underpinning reasons for your enthusiasm.

I believe the truth will prevail. Time will tell.

Xaar,

ReplyDeleteI first contacted Adam after I noticed an article about Obbligato products.

Adam had mistakenly called it either carbon fiber or graphite. I told him

what the material was, and ask him to change the description, and I used

the term diamond like carbon too. Many people are quite confused about

carbon, and it's allotrope's besides (You). Most material scientist hate the

term DLC because it makes people think that a DLC is something like diamond

not one of them are. DLC is a scientific term used for any carbon that has any property that diamond has mostly for hardness which are the most like diamond.

I also picked the trade mark name Black Diamond because most people like (You) think any Black form of carbon is graphite, CF, or carbon carbon.

I also had to explain to Dr. Jack C Bokros why I picked that name. He developed this carbon at General Atomic in the early 1960's. He hates the term DLC used on carbons because they then think it is diamond. You however helped to prove to him, and others the need to try to educate people about carbon. There are four possible forms of diamond most are Tetrahedral or Cubic (lonsdaleite), and they can form in nature or be made in a lab. Some DLC's are mostly SP3 bonds, and others like pyrolytic carbon have SP1, SP2, and SP3 bonds at random, and is isotropic, covalently bonded like diamond.

The big mistake (You) have made here is you seem to think this carbon is pyrolytic graphite it is not. Pyrolytic carbon is the common name used by material scientist for (low temperature turbostratic isotropic pyrolytic carbon) or (PyC).

You can also find many papers (some claim to be scholary too) on the web that show pyrolytic graphite levitating over rear Earth permanent magnets, and then

go on to say it is also used in blood contacting devices like mechanical heart valves. No wonder some are so confused about the two very different forms of carbon. You are right to say pyrolytic graphite is not a DLC. We had to quote the hand book of carbon to the USPTO inspector, and his supervisor to prove to them that (PyC) is not graphite. The Korean patent office that did the international patent search was much better informed on carbon.

There are also many other reasons for the trademark name Black Diamond.

Many for hundreds of years have speculated that diamond would solve

all of the problems of stringed musical instruments which (PyC) does too. Many of the top Phd material scientist have told me that (PyC) is a better conductor of acoustic energy that diamond too. Diamond also would be much harder

( yes I intended the pun) to work with, and much more expensive too.

Both diamond, and (PyC) make permanent frets, nuts, saddles, and picks etc.

Which out preform any other material I have ever seen or heard too. I hope this clears up any misconceptions you might have from Adam's article too.

Regards

Jim

awesome,

ReplyDeletethank you so much for sharing such an wesome

blog..

really i like your site.

i enjoyed...

acrylic lecterns